We are all very impressed with your facility, capabilities, strength of knowledge in your products and especially satisfied with the quality of work you deliver. Thanks again to all in the Apex team and look forward to our next project together

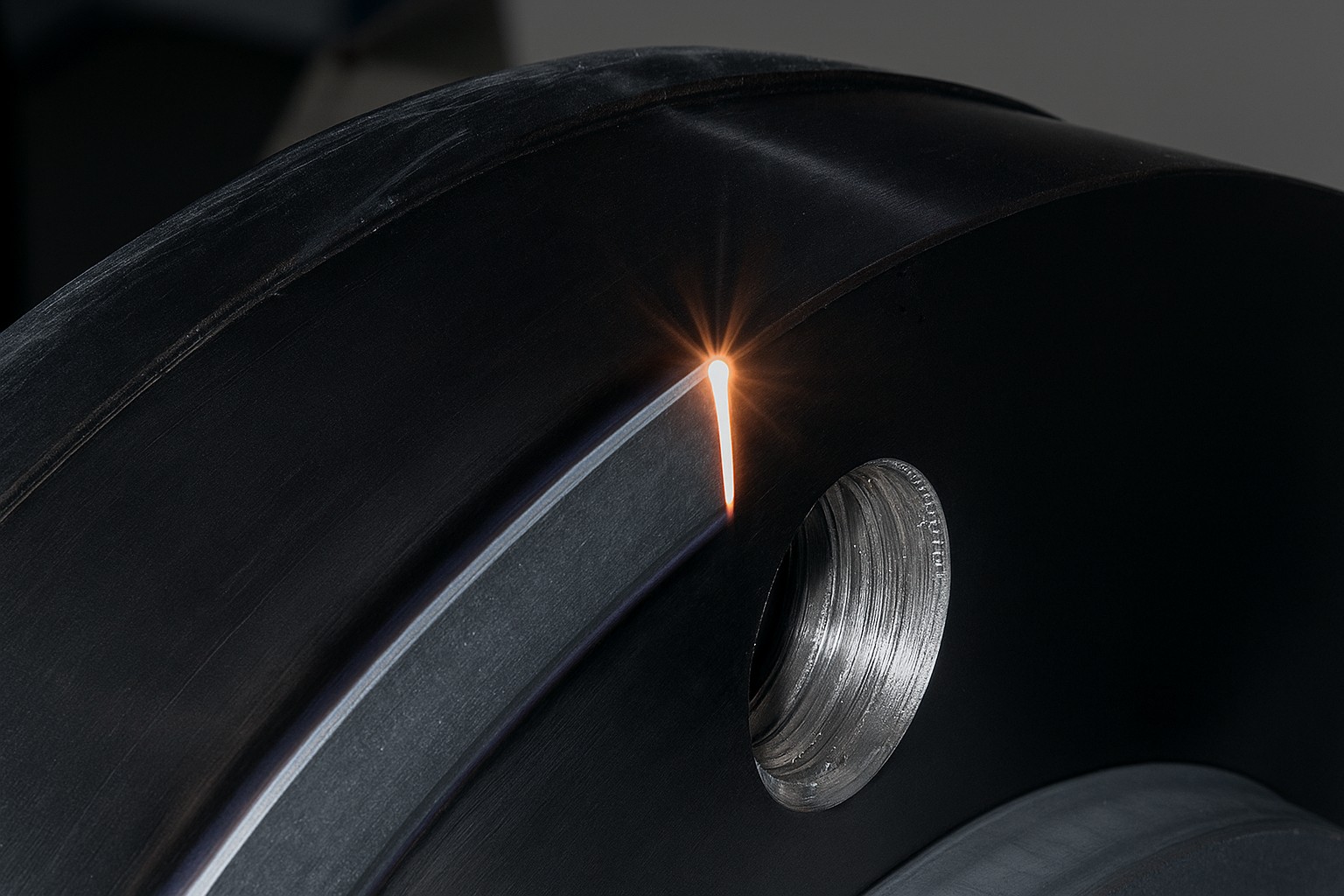

Achieve precise case depth and limited distortion, without compromising on part/tool performance and quality. The process is inherently a LEAN (single piece flow) process with high processing speed, precision heating control, as well as being highly flexible, easily handling most work piece shapes and geometries.

Transform your components with laser heat treatment that delivers measurable performance improvements. Our advanced process enhances durability while maintaining exact specifications.

APEX ETG’s laser heat treatment service transforms your critical components through precision surface hardening. Our high-power diode laser technology creates hardened surfaces with precise case depths. The localised heating process ensures negligible distortion, eliminating costly post-processing while delivering enhanced wear, fatigue, and corrosion resistance. With processing speeds up to three times faster than traditional methods, we help you reduce production time and costs while improving component performance.

We are all very impressed with your facility, capabilities, strength of knowledge in your products and especially satisfied with the quality of work you deliver. Thanks again to all in the Apex team and look forward to our next project together

I just want to convey my appreciation for the good work that APEX has done for us. I have just been informed the components APEX repaired for us have exceeded all expectations. We have just crossed the 3x lifecycle benchmark. We would like to develop more applications with the team at APEX.

The game-changer for us to adopt laser cladding as our standard repair method was APEX’s willingness to undergo our supplier qualification process, to produce test tokens for laboratory and mechanical testing, and to adopt our quality control standards from the beginning. We look forward to develop more applications together with Apex ETG.

Laser cladding can significantly extend component service life by up to 100% when compared to standard parts performance.

This dramatic improvement comes from the mechanical properties of high-performance alloys applied to the surface and from the metallurgically bonded protective coating, keeping your critical equipment operational longer.

High-speed laser cladding (HSLC) delivers productivity gains of up to 300% over traditional coating methods. The combination of faster scanning speeds and minimal post-processing requirements means your components are back in service sooner with better performance.

Our laser cladding turnaround time average over the last 3 years is 10 working days. Depending on the component overall dimensions and weight our team will collaborate with you to design an efficient repair process.

Targeted material deposition through laser cladding achieves 10-20% weight reduction in aerospace and automotive applications. This precision approach eliminates bulky protective coatings while maintaining superior protection, improving both energy efficiency and overall performance.

Laser cladding can help optimise the following mechanical properties:

Hardness, Wear Resistance, Corrosion Resistance, Fatigue Strength, Toughness, Thermal Stability and Bond Strength.

Get in touch for a free consultation with one of our experienced team members. APEX ETG has all of your application needs covered.