Main Causes Of Wear In The Drilling Industry

-

Abrasive wear

Some drilling applications involve working with abrasive materials, which can accelerate wear and tear on drilling parts, leading to the need for repair.

-

Erosion

In some drilling applications, the drilling fluid or slurry used to lubricate the drilling process can cause erosion of the surfaces of drilling parts.

-

Corrosion

Exposure to harsh chemicals, moisture, or other corrosive substances can cause corrosion of drilling parts, leading to weakened performance and eventual failure.

-

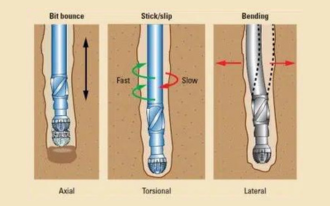

Impact and shock

Drilling operations can encounter unexpected obstructions, rocks, or other hard objects that can cause impact and shock to the equipment. This sudden stress can result in damage to the drilling parts.

-

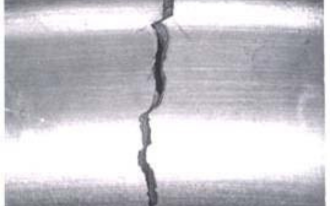

Fatigue and deformation

Repeated use and cyclic loading can induce fatigue in drilling parts, causing them to weaken and deform over time.

-

Wear and tear

The repetitive nature of drilling operations exposes drilling parts to continuous wear and tear, which can lead to failure or reduced efficiency.

-

High-stress environments

Drilling equipment often operates in challenging environments characterized by extreme temperatures, pressure differentials, and exposure to corrosive substances. These conditions can accelerate the degradation of drilling parts, necessitating repair.

-

Environmental factors

Natural factors such as weather conditions, humidity, and exposure to water or chemicals can contribute to the deterioration of drilling parts, making laser cladding repairs necessary.

Discover The Benefits Of Laser Cladding For Drilling!

Elevate your drilling expertise with APEX ETG’s cutting-edge laser cladding services. Stay ahead of the competition, maximise performance, and optimise your bottom line. Contact us today to explore how our solutions can revolutionise your drilling operations.

Benefits of APEX ETG’s laser cladding services!

Unparalleled Wear Resistance: Our laser cladding solutions redefine durability, enhancing the wear resistance of drilling components to withstand the harshest drilling conditions. Experience extended component lifespan and minimise costly replacements.

Superior Corrosion Protection: Our advanced laser cladding process creates a formidable defence against corrosion for your drilling components. Combat the corrosive challenges of drilling fluids and harsh environments while maintaining peak performance.

Tailored Material Properties: Gain complete control over material properties with APEX ETG’s laser cladding expertise. We customise hardness, strength, and thermal conductivity to match your drilling demands precisely. Unlock unparalleled performance and efficiency.

Streamlined Repairs: Our laser cladding services are reliable and efficient for repairing worn or damaged drilling components. Minimise downtime, maximise productivity and optimise maintenance costs with our swift and precise repair capabilities.

Unleash Design Potential: Experience unprecedented design freedom with our precise laser cladding process. Craft intricate shapes and optimised geometries that enhance fluid flow, heat dissipation, and overall drilling performance. Let innovation thrive.

Cost-Effective and Sustainable: Longer lifespans result in fewer change-outs and reduced maintenance and downtime costs. Increased efficiencies reduce total overall costs as well as carbon footprint. Enhance your profitability while reducing your ecological footprint.

Applications

- Drill bits and rods

- Auger flights, blades, housings and shafts

- Core barrels, stabilisers and lifter cases

- Hammer bits

- Subs and joints

- Polycrystalline diamond compact (PDC) cutters

- Downhole tools

APEX ETG’s Surface Solutions for the Australian Drilling Industry

APEX ETG’s laser cladding services offer a range of benefits for drilling equipment, including improved wear resistance, longer service life, improved surface finish, reduced friction, repair of damaged drilling parts, and reduced need for expensive replacements. Common causes of wear on drilling parts include abrasive materials, high temperature, high pressure, and repeated use. Laser cladding can benefit various components used in drilling operations, such as auger flights, teeth, blades, core barrels, rods, bits, drill collars, stabilisers, reamers, samplers, tubes, and tube liners.