Our products and services provide effective, cost-saving solutions to address the most demanding wear problems. From dealing with normal sliding abrasion at room temperature to aggressive chemical corrosion at elevated temperatures, we have the wear solutions to keep equipment running for longer periods and at optimised production rates.

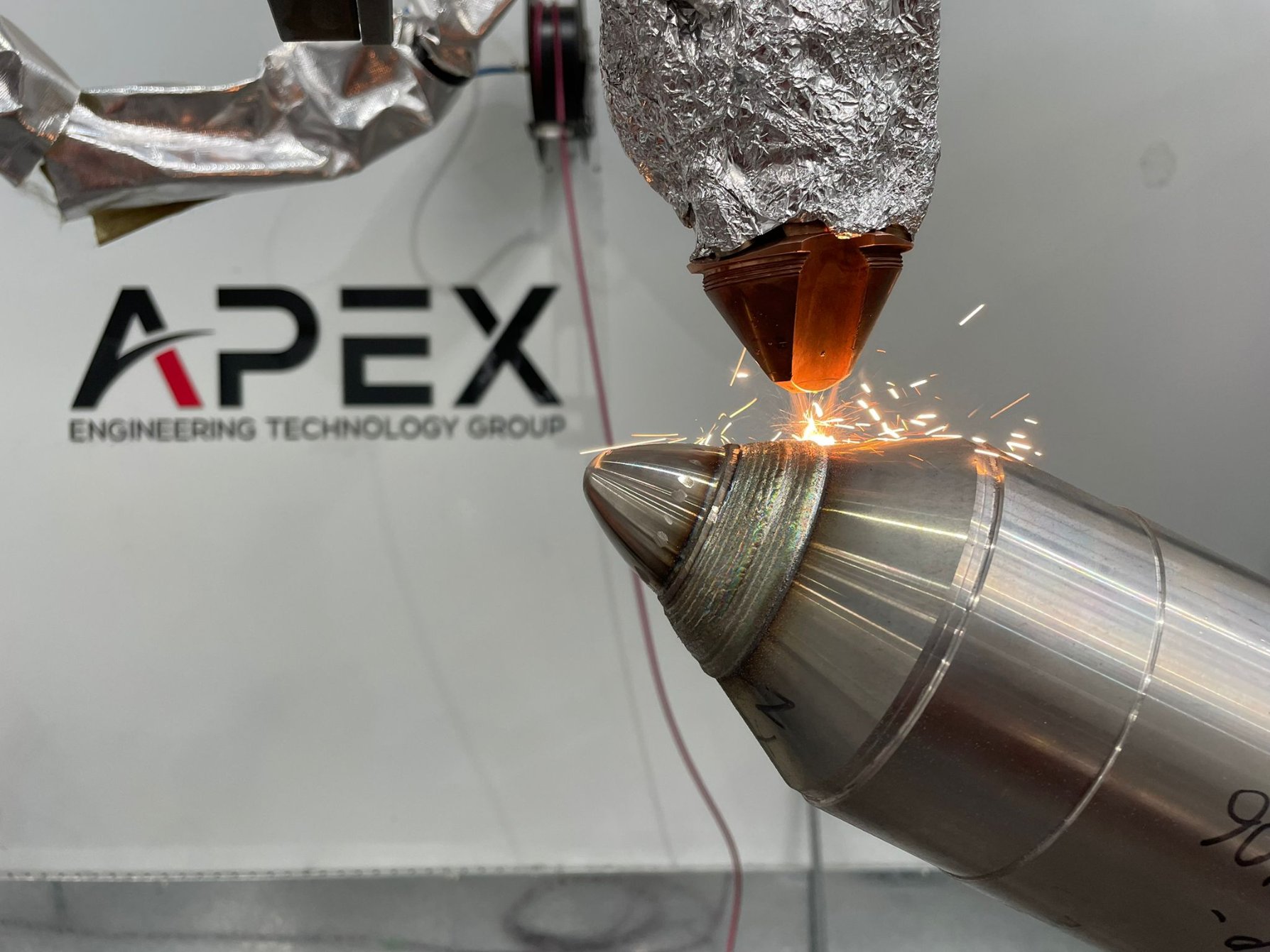

Laser cladding wear parts with superior metal coatings protect them against abrasion, corrosion, chemical attack, and wear under extreme pressures.

APEX ETG provide superior solutions for exploration, drilling, corrosion resistance, and hardfacing applications. With widespread usage in oil refinery process plants, downhole stabilisers, valves, and hydraulic rods, laser cladding enhances crucial components such as bearings, rods, and seals. Applications can include:

Our technology is built for performance. By reclaiming and enhancing critical components, we help reduce downtime, extend service life, and improve equipment productivity — all with faster, more efficient turnaround times than conventional methods.

Offshore and refinery equipment faces aggressive chemical and saltwater corrosion that destroys unprotected surfaces within months. Laser cladding creates an impermeable barrier, protecting valves, pumps, and piping systems from chemical attack while maintaining dimensional integrity.

Drilling fluids, production sand, and high-velocity flows erode critical components rapidly.

Gas turbines and refinery equipment endure temperature swings exceeding 800°C, causing thermal fatigue and oxidation.

Achieve 4-6x longer component life with corrosion-resistant alloys that outperform traditional coatings. Our laser cladding prevents stress corrosion cracking and pitting in harsh environments.

Prevent unplanned shutdowns with proactive surface protection. Our precision-engineered solution capabilities keep critical assets operational when failure isn’t an option.

Australia’s oil and gas sector loses billions of dollars annually to corrosion and equipment degradation. Operating in extreme conditions – from offshore platforms battling saltwater corrosion to refineries processing aggressive chemicals at high temperatures – critical components face relentless exposure and wear. Traditional maintenance means frequent replacements, production interruptions, and safety risks. APEX ETG’s laser cladding technology offers high-quality asset integrity management. Our metallurgically bonded coatings provide superior protection against corrosion, erosion, and wear while maintaining precise tolerances essential for sealing surfaces and rotating equipment. Help meet production targets and safety standards simultaneously.

APEX ETG specialises in oil and gas applications requiring exceptional precision and reliability. Complete in-house machining, testing, and certification capabilities ensure your critical assets return to service meeting all specifications and compliance requirements.

Laser cladding can significantly extend component service life by up to 100% when compared to standard parts performance.

This dramatic improvement comes from the mechanical properties of high-performance alloys applied to the surface and from the metallurgically bonded protective coating, keeping your critical equipment operational longer.

High-speed laser cladding (HSLC) delivers productivity gains of up to 300% over traditional coating methods. The combination of faster scanning speeds and minimal post-processing requirements means your components are back in service sooner with better performance.

Our laser cladding turnaround time average over the last 3 years is 10 working days. Depending on the component overall dimensions and weight our team will collaborate with you to design an efficient repair process.

Targeted material deposition through laser cladding achieves 10-20% weight reduction in aerospace and automotive applications. This precision approach eliminates bulky protective coatings while maintaining superior protection, improving both energy efficiency and overall performance.

Laser cladding can help optimise the following mechanical properties:

Hardness, Wear Resistance, Corrosion Resistance, Fatigue Strength, Toughness, Thermal Stability and Bond Strength.

Get in touch for a free consultation with one of our experienced team members. APEX ETG has all of your application needs covered.