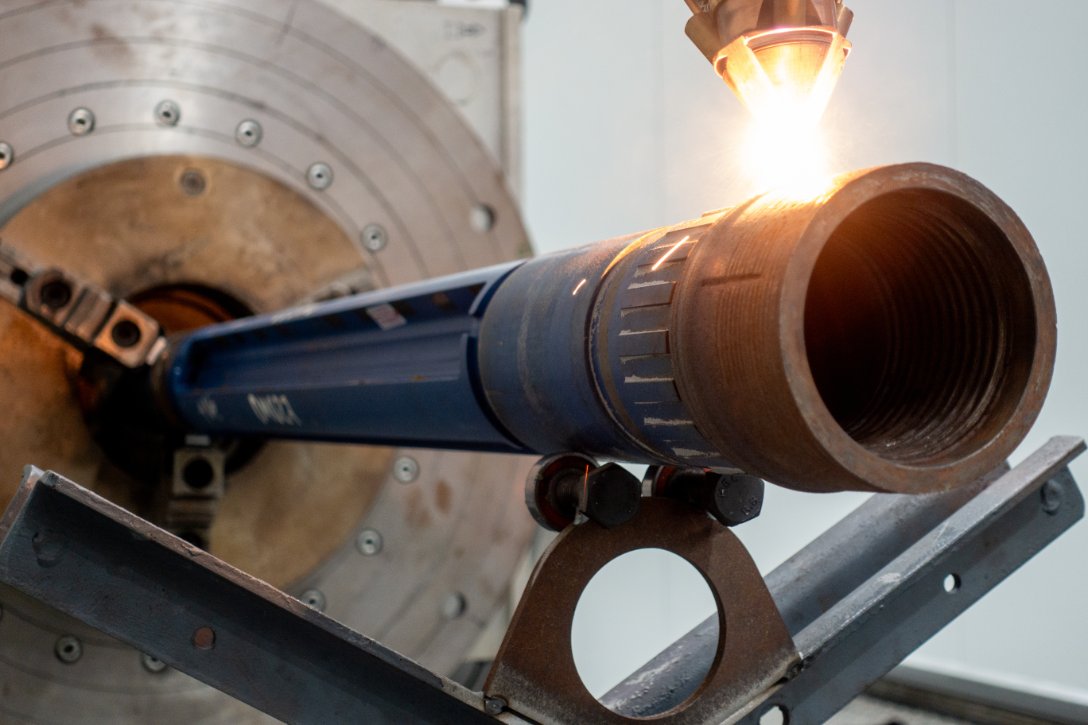

Revitalise your drilling equipment with laser cladding technology that restores dimensions, enhances wear resistance, and boosts strength. APEX ETG delivers surface engineering solutions that extend component life, minimise downtime, and reduce replacement costs for drilling components.

Our technology is built for performance. By reclaiming and enhancing critical components, we help reduce downtime, extend service life, and improve equipment productivity — all with faster, more efficient turnaround times than conventional methods.

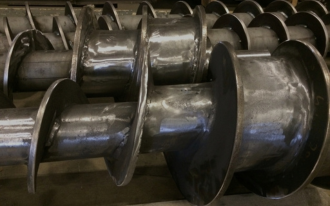

Working with abrasive materials accelerates wear on drilling parts, grinding away protective surfaces rapidly.

Drilling operations encounter unexpected obstructions and hard rock formations that cause sudden impact and shock. APEX ETG’s impact-resistant coatings absorb and distribute these forces, preventing cracks, deformation, and catastrophic failure of critical drilling components.

Drilling fluids and slurries cause severe erosion while moisture and chemicals create corrosive environments. Our alloy coatings provide dual protection, maintaining component integrity and performance throughout extended drilling campaigns.

Enhance drilling component durability with wear-resistant coatings that withstand the harshest conditions. Our laser cladding solutions redefine equipment longevity, minimising costly replacements and maximising operational uptime.

Combat corrosive drilling fluids and harsh environments with advanced protective coatings. Our process creates a formidable defence that maintains peak performance while preventing degradation of critical components.

Drilling operations push equipment to the absolute limit. Continuous abrasion from rock and minerals, massive impact forces, and corrosive drilling fluids destroy critical components rapidly – leading to frequent replacements and costly downtime. Traditional repair methods offer temporary solutions that fail to address the root causes of wear. APEX ETG’s laser cladding technology transforms drilling equipment maintenance. Our advanced hardfacing process creates metallurgically bonded protective layers that withstand extreme conditions while maintaining precise tolerances. From drill bits to stabilisers, we help drilling contractors achieve unparalleled performance and reliability while significantly reducing operational costs.

APEX ETG brings cutting-edge laser cladding expertise to the drilling industry. With an extensive range of tailored machining services, we provide comprehensive solutions for all drilling applications.

Laser cladding can significantly extend component service life by up to 100% when compared to standard parts performance.

This dramatic improvement comes from the mechanical properties of high-performance alloys applied to the surface and from the metallurgically bonded protective coating, keeping your critical equipment operational longer.

High-speed laser cladding (HSLC) delivers productivity gains of up to 300% over traditional coating methods. The combination of faster scanning speeds and minimal post-processing requirements means your components are back in service sooner with better performance.

Our laser cladding turnaround time average over the last 3 years is 10 working days. Depending on the component overall dimensions and weight our team will collaborate with you to design an efficient repair process.

Targeted material deposition through laser cladding achieves 10-20% weight reduction in aerospace and automotive applications. This precision approach eliminates bulky protective coatings while maintaining superior protection, improving both energy efficiency and overall performance.

Laser cladding can help optimise the following mechanical properties:

Hardness, Wear Resistance, Corrosion Resistance, Fatigue Strength, Toughness, Thermal Stability and Bond Strength.

Get in touch for a free consultation with one of our experienced team members. APEX ETG has all of your application needs covered.