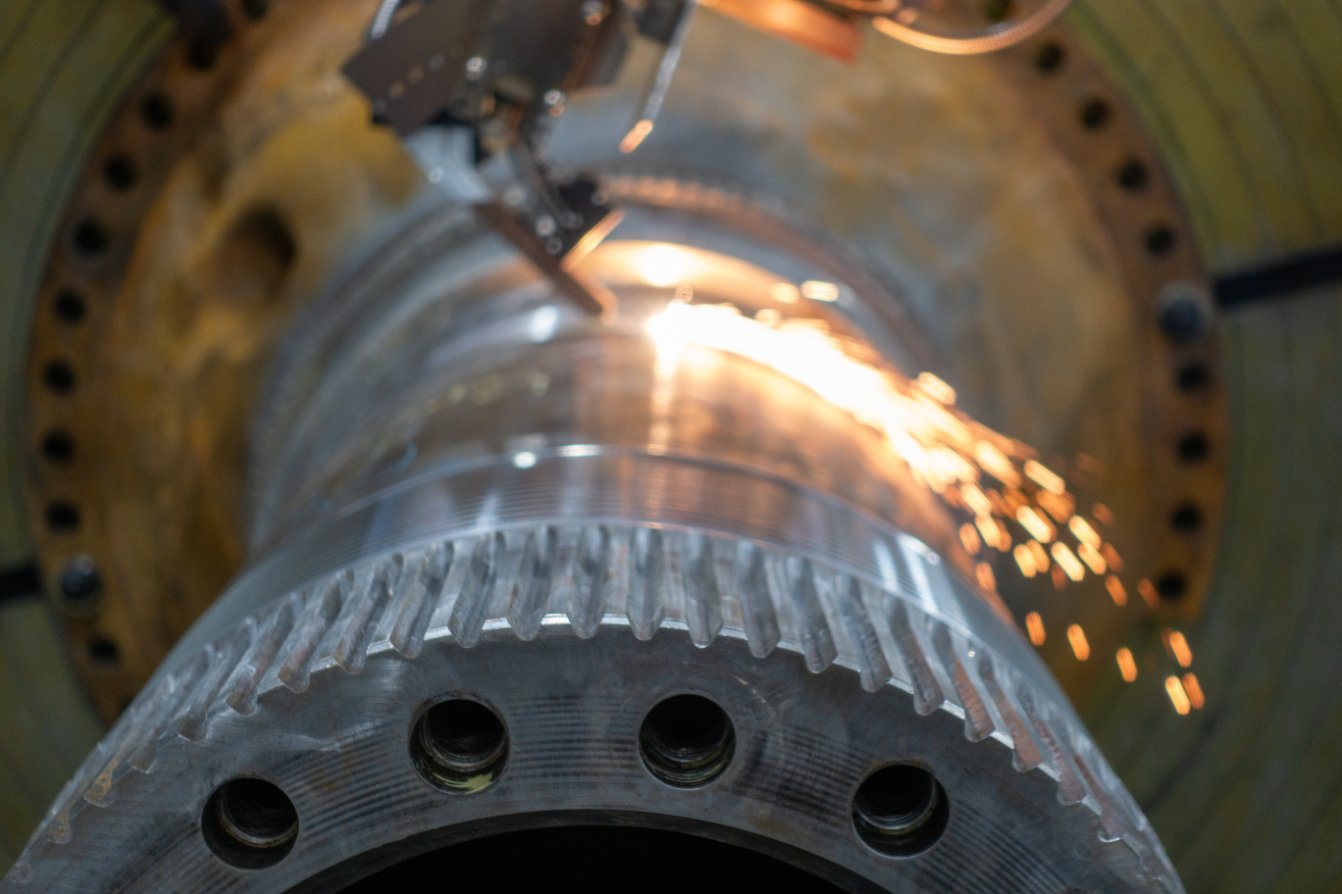

Optimise the operational integrity of defence-grade systems with advanced laser cladding technology, across terrestrial, maritime and aerospace platforms. APEX ETG specialises in precision surface engineering, utilising high-energy laser deposition to restore and enhance critical component surfaces. Our component solutions increase wear resistance, mitigate fatigue and corrosion failures, and extend mean time between overhauls (MTBO), directly supporting defence lifecycle sustainment and readiness objectives.

For the reinforcement, repair and enhancement of components for land, air, and sea. Our solutions may be applied to:

Our technology is built for performance. By reclaiming and enhancing critical components, we help reduce downtime, extend service life, and improve equipment productivity — all with faster, more efficient turnaround times than conventional methods.

Naval vessels face relentless saltwater corrosion that degrades propulsion systems, hulls, and deck machinery. Our corrosion-resistant laser cladding protects essential components including propeller shafts, pump impellers, and valve systems, ensuring fleet readiness and operational reliability.

Ground vehicles like Bushmasters endure severe wear on suspension and drivetrain components from harsh terrain. APEX ETG’s wear-resistant coatings strengthen critical parts, extending vehicle lifespan and maintaining mobility in demanding operational environments.

Aircraft engines and turbine systems face extreme thermal cycling that causes fatigue and degradation. Our specialised coatings enhance heat resistance in turbine blades and combustion components, supporting the performance demands of fleets.

Combat marine corrosion with advanced coatings that protect navy vessels’ critical systems. Our technology shields propulsion components, ventilation systems, and external surfaces from saltwater degradation.

Strengthen wear-prone components with surface enhancements that withstand extreme operational demands. Perfect for ground vehicle suspension systems, final drives, and high-stress mechanical parts.

Australian Defence Force operations demand absolute reliability from equipment performing in the world’s harshest environments. From Bushmaster vehicles in desert conditions to naval vessels battling marine corrosion, component failure compromises mission readiness and personnel safety. Traditional maintenance often means costly replacements and extended downtime that impact operational capability. APEX ETG’s laser cladding technology delivers defence-grade solutions that meet the ADF’s exacting standards. Our ISO 9001:2015 certified processes provide metallurgically bonded coatings that enhance corrosion resistance, wear durability, and thermal management. Support defence readiness while advancing sustainability goals through component remanufacturing that extends service life and reduces resource consumption.

APEX ETG brings advanced laser cladding expertise to Defence applications across all domains. Our capabilities span from precise turbine blade restoration for RAAF aircraft to large-scale propeller shaft repairs for RAN vessels.

Laser cladding can significantly extend component service life by up to 100% when compared to standard parts performance.

This dramatic improvement comes from the mechanical properties of high-performance alloys applied to the surface and from the metallurgically bonded protective coating, keeping your critical equipment operational longer.

High-speed laser cladding (HSLC) delivers productivity gains of up to 300% over traditional coating methods. The combination of faster scanning speeds and minimal post-processing requirements means your components are back in service sooner with better performance.

Our laser cladding turnaround time average over the last 3 years is 10 working days. Depending on the component overall dimensions and weight our team will collaborate with you to design an efficient repair process.

Targeted material deposition through laser cladding achieves 10-20% weight reduction in aerospace and automotive applications. This precision approach eliminates bulky protective coatings while maintaining superior protection, improving both energy efficiency and overall performance.

Laser cladding can help optimise the following mechanical properties:

Hardness, Wear Resistance, Corrosion Resistance, Fatigue Strength, Toughness, Thermal Stability and Bond Strength.

Get in touch for a free consultation with one of our experienced team members. APEX ETG has all of your application needs covered.