Maximise construction equipment performance with laser cladding technology that combats wear, impact, and corrosion. APEX ETG delivers surface engineering solutions for heavy machinery, hydraulic systems, and steel components that extend service life and reduce operational costs.

Enhance the durability of components, extend their lifespan and improving overall performance of machinery. Our process provides wear and corrosion resistance, ensuring optimal functionality even in harsh operating conditions. Additionally, laser cladding allows for precise customisation, enabling complex geometries and tailored surface properties to optimise component performance.

Our technology is built for performance. By reclaiming and enhancing critical components, we help reduce downtime, extend service life, and improve equipment productivity — all with faster, more efficient turnaround times than conventional methods.

Construction equipment faces corrosion from weather, chemicals, and harsh site conditions that degrade unprotected surfaces. Corrosion-resistant coatings can protect critical components, maintaining equipment integrity and reducing replacement frequency significantly.

Mobile cranes, excavators, and heavy equipment endure enormous loads and continuous cycling that fatigue critical components. APEX ETG’s high-strength coatings reinforce stress points and prevent premature failure, keeping equipment operational on demanding construction sites.

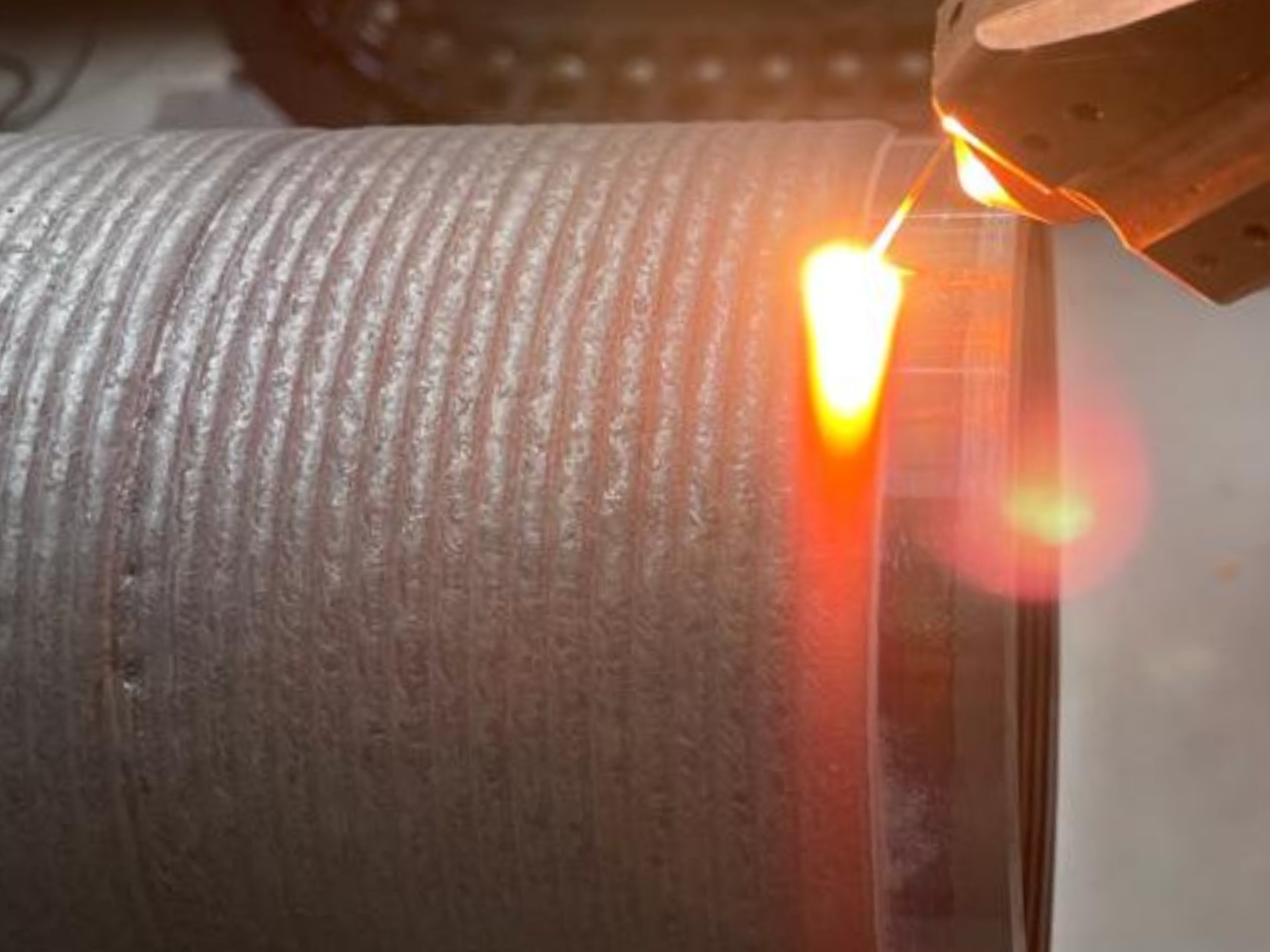

Construction machinery relies heavily on hydraulic systems that face constant wear from high pressures and contamination. Our laser cladding restores hydraulic cylinders, pistons, and valve components to precise dimensions while adding superior wear resistance for extended service life.

Multiply component lifespan with metallurgically bonded coatings that resist wear, impact, and corrosion. Reduce equipment downtime and replacement costs while maintaining peak operational performance. Help construction operations meet project deadlines and budget targets through dramatically extended equipment life and reduced maintenance requirements.

Restore worn hydraulic components to exact specifications with precision laser cladding. Our process rebuilds cylinders, rods, and valves while adding wear-resistant surfaces that can outperform original equipment.

Construction equipment operates in demanding environments where constant wear, extreme loads, and harsh conditions are the norm. Components are continuously battling corrosion, excavators are under continuous stress, equipment failure means project delays and mounting costs. Traditional maintenance approaches require frequent part replacements and extended downtime. APEX ETG’s advanced surface solutions protect critical components from wear and damage while maintaining precise tolerances essential for smooth operation.

APEX ETG specialises in construction equipment applications requiring durability and precision. Our high-power laser systems deliver superior coatings with minimal heat input, preventing distortion while achieving exceptional wear resistance. Complete machining capabilities ensure components return to service meeting exact specifications.

Laser cladding can significantly extend component service life by up to 100% when compared to standard parts performance.

This dramatic improvement comes from the mechanical properties of high-performance alloys applied to the surface and from the metallurgically bonded protective coating, keeping your critical equipment operational longer.

High-speed laser cladding (HSLC) delivers productivity gains of up to 300% over traditional coating methods. The combination of faster scanning speeds and minimal post-processing requirements means your components are back in service sooner with better performance.

Our laser cladding turnaround time average over the last 3 years is 10 working days. Depending on the component overall dimensions and weight our team will collaborate with you to design an efficient repair process.

Targeted material deposition through laser cladding achieves 10-20% weight reduction in aerospace and automotive applications. This precision approach eliminates bulky protective coatings while maintaining superior protection, improving both energy efficiency and overall performance.

Laser cladding can help optimise the following mechanical properties:

Hardness, Wear Resistance, Corrosion Resistance, Fatigue Strength, Toughness, Thermal Stability and Bond Strength.

Get in touch for a free consultation with one of our experienced team members. APEX ETG has all of your application needs covered.