Shield critical assets from chemical attack and environmental degradation. Our corrosion-resistant laser cladding solutions protect equipment in harsh conditions, extending service life and reducing the billions in annual cost of corrosion to Australian industry.

Protect equipment exposed to corrosive environments and extreme conditions across oil & gas, mining, marine and chemical processing industries.

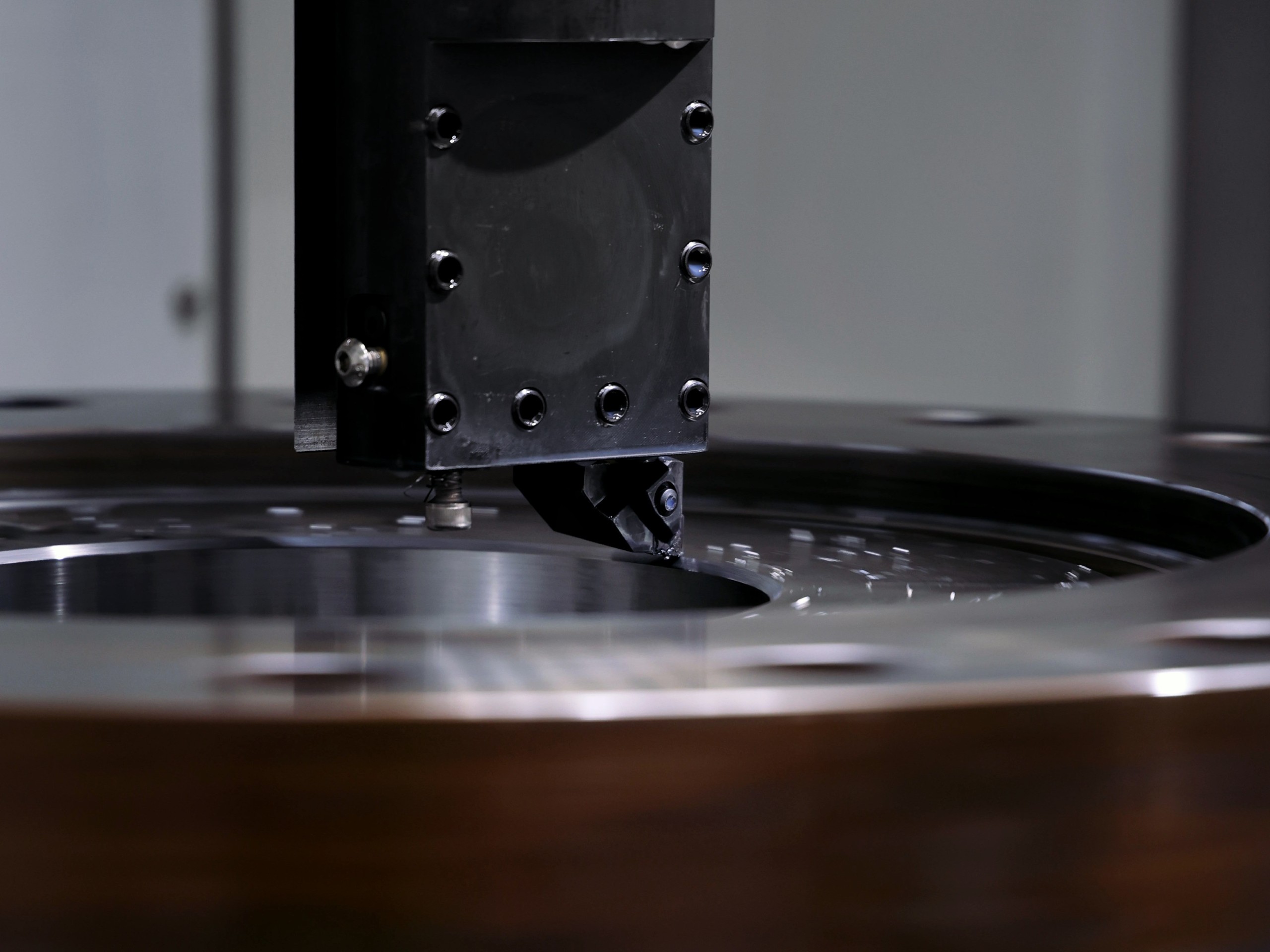

Nickel-based and stainless steel alloys resist chemical attack in acidic, alkaline and marine conditions. Metallurgical bonding ensures coatings won’t flake or peel under extreme conditions

Components last significantly longer with corrosion-resistant cladding. Reduce replacement frequency, minimise maintenance shutdowns, and lower total operational costs.

Corrosion costs the global industrial sector and estimated US$2.5 trillion annually, with Australian industries alone spending AU$78 billion on remediation. APEX ETG’s laser cladding technology applies corrosion-resistant alloys—including stainless steel and nickel-based materials—to vulnerable components. Our metallurgically bonded coatings provide superior protection against acidic, alkaline and saltwater environments. The result: longer service life, improved efficiency, reduced replacement costs and minimised environmental impact.

Laser cladding can significantly extend component service life by up to 100% when compared to standard parts performance.

This dramatic improvement comes from the mechanical properties of high-performance alloys applied to the surface and from the metallurgically bonded protective coating, keeping your critical equipment operational longer.

High-speed laser cladding (HSLC) delivers productivity gains of up to 300% over traditional coating methods. The combination of faster scanning speeds and minimal post-processing requirements means your components are back in service sooner with better performance.

Our laser cladding turnaround time average over the last 3 years is 10 working days. Depending on the component overall dimensions and weight our team will collaborate with you to design an efficient repair process.

Targeted material deposition through laser cladding achieves 10-20% weight reduction in aerospace and automotive applications. This precision approach eliminates bulky protective coatings while maintaining superior protection, improving both energy efficiency and overall performance.

Laser cladding can help optimise the following mechanical properties:

Hardness, Wear Resistance, Corrosion Resistance, Fatigue Strength, Toughness, Thermal Stability and Bond Strength.

Get in touch for a free consultation with one of our experienced team members. APEX ETG has all of your application needs covered.