Main Causes Of Wear For Hydraulics

-

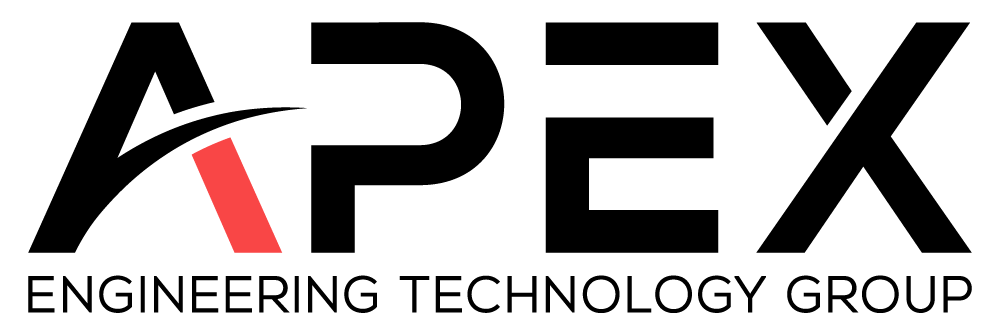

Abrasive Wear

Solid particles like dirt, debris, or metal shavings can enter the hydraulic system, causing abrasive wear as they come into contact with components.

APEX ETG’s laser cladding process ensures the metallurgical bonding of a wear-resistant coating, providing enhanced resistance against abrasive wear.

-

Adhesive Wear

Adhesive wear occurs when sliding surfaces come into direct contact, resulting in friction and material transfer. This leads to surface damage and shortened component lifespan.

Laser cladding prevents adhesive wear by applying a wear-resistant coating with a low friction coefficient. This protective layer minimises direct contact, reducing wear and extending component lifespan.

-

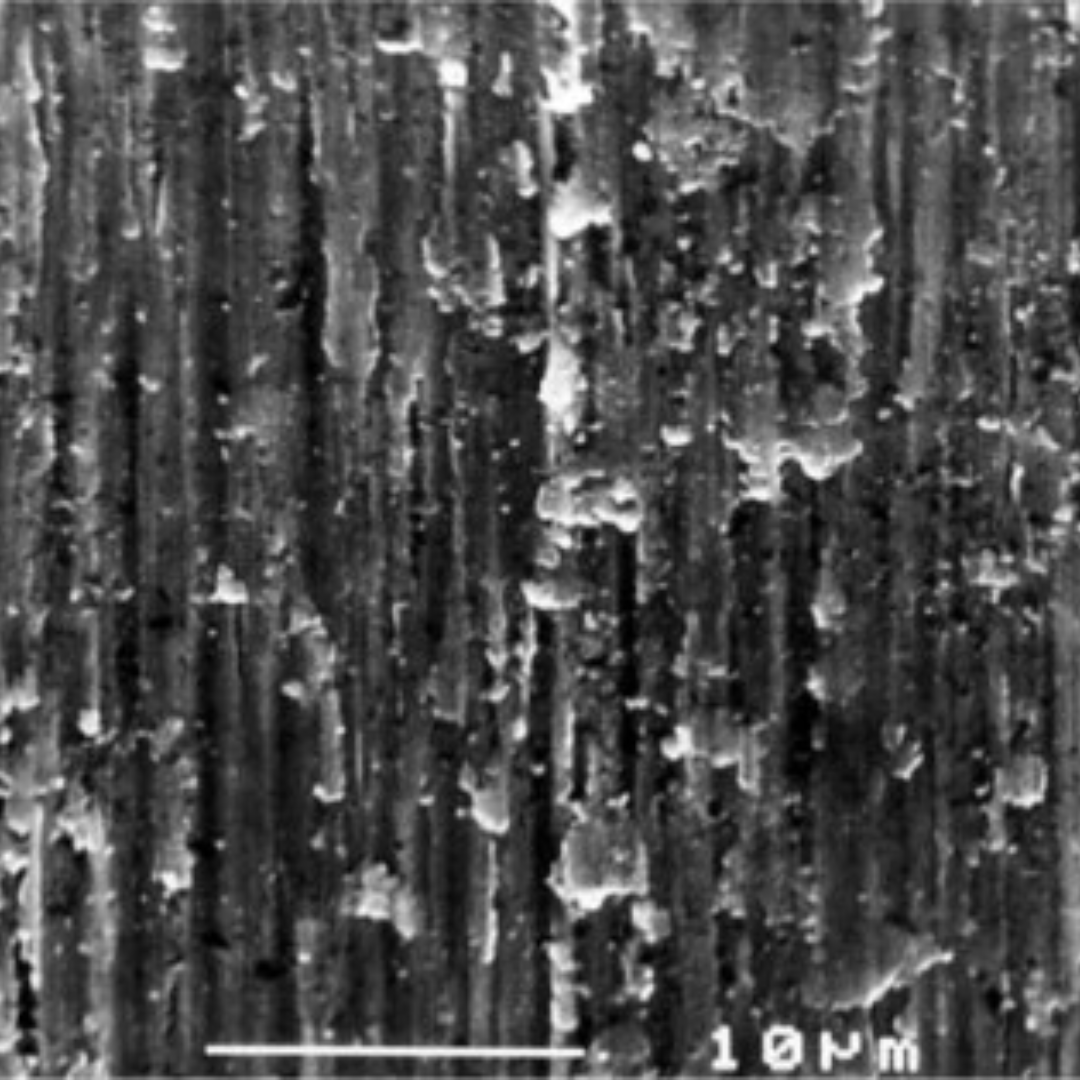

Cavitation Erosion

Cavitation erosion results from forming and collapsing vapor bubbles in a fluid due to rapid pressure changes. This phenomenon can cause severe damage to hydraulic components, especially in areas of low pressure.

APEX ETG’s laser cladding enhances resistance to bubble collapse by depositing a specialised coating, protecting hydraulic components from material degradation.

-

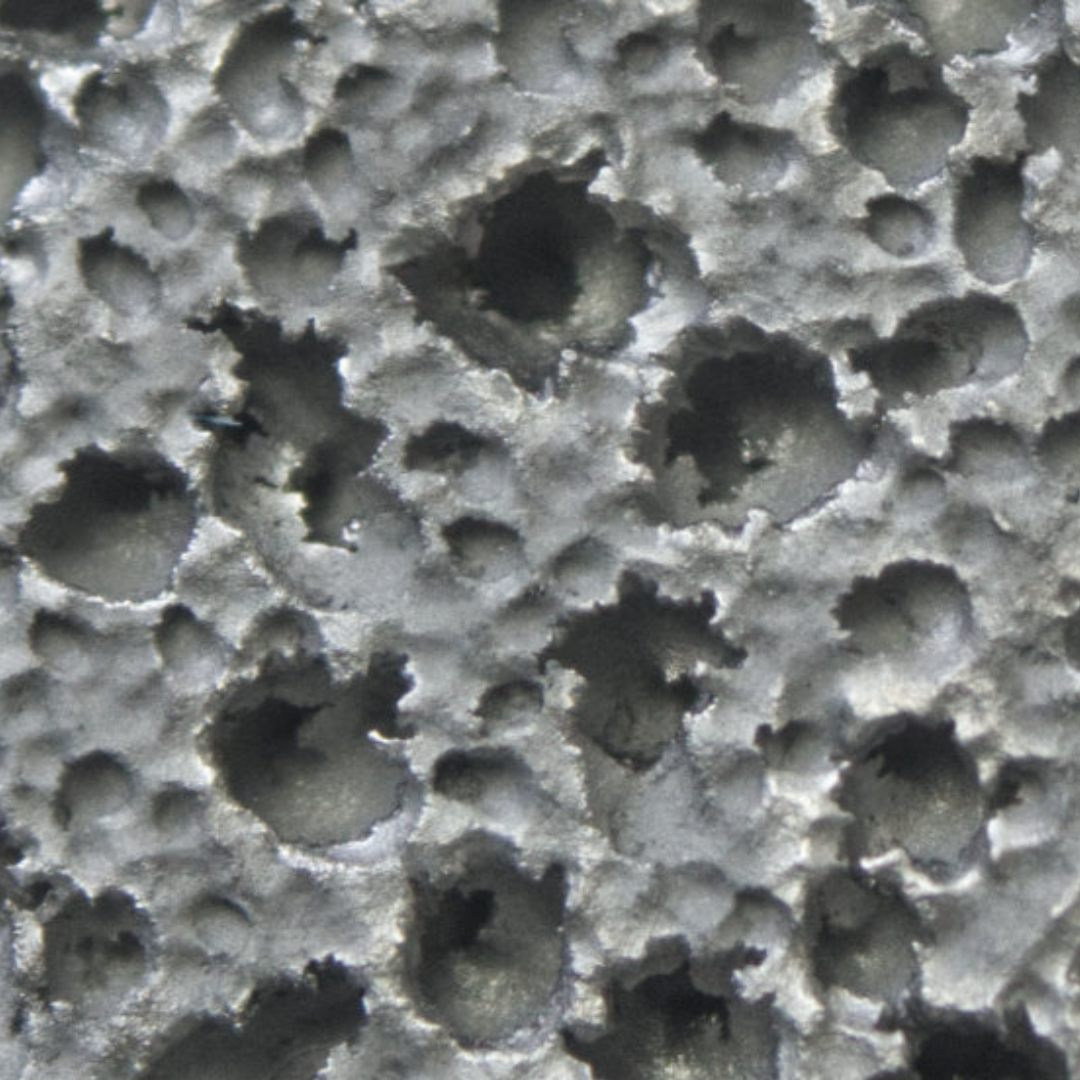

Erosive Wear

Erosive wear occurs when high-velocity fluid or particulate matter impinges on hydraulic components, leading to surface erosion and material loss. Components exposed to fluid flow include valves, pump impellers and nozzles.

We apply a wear-resistant coating with high hardness and excellent erosion resistance. The coating acts as a sacrificial layer, absorbing the erosive forces and preserving the integrity of the underlying component.

Discover The Benefits Of Laser Cladding For Hydraulics!

APEX ETG’s laser cladding revolutionises hydraulic systems by offering a myriad of benefits. It fortifies components against abrasive wear with wear-resistant coatings, combating the destructive forces of particles and debris. Minimising direct contact and material transfer mitigates adhesive wear, prolonging the lifespan of components. Laser cladding’s protective layers also resist erosive wear caused by high-velocity fluids, ensuring the integrity of hydraulic parts. Furthermore, it shields against cavitation erosion, preventing damage from forming and collapsing vapour bubbles. With laser cladding, hydraulic systems become resilient, reliable, and ready to conquer the challenges of wear, ensuring enhanced performance and reduced maintenance costs.

Enhanced Wear Resistance: Laser cladding offers superior wear resistance compared to traditional methods. It provides a specialised metallurgically bonded coating that can withstand the harsh forces of abrasion, adhesion, and erosion commonly encountered in hydraulic systems. This ensures a prolonged component lifespan and reduces the need for frequent replacements or repairs.

Customised Material Selection: Laser cladding allows for a wide range of materials to be used for the coating, including carbides and composites. This flexibility enables experts to select the most suitable coating material tailored to the specific wear challenges they encounter in hydraulic applications. It ensures optimised performance and reliability.

Precise and Controlled Coating Application: Laser cladding provides precise and controlled coating deposition. With a focused laser beam, experts can achieve accurate coating thickness and uniform distribution. This level of control minimises the risk of excessive buildup or uneven coatings, ensuring consistent performance across hydraulic components.

A Solution to Environmental Concerns: Laser cladding offers a more environmentally friendly alternative to traditional methods like hard chrome plating. By using powder-based materials, it avoids the use of toxic chemicals, such as hexavalent chromium found in hard chrome plating. This addresses environmental concerns while still delivering excellent wear resistance and component protection.

Strong Metallurgical Bonding: Laser cladding ensures excellent metallurgical bonding between the coating and the substrate. This strong bond enhances adhesion, minimising the risk of delamination or flaking. It guarantees the durability and integrity of the coated hydraulic components, even under demanding operational conditions.

Efficient Repair and Restoration: Laser cladding provides an efficient solution for repairing and restoring worn or damaged hydraulic components. Selectively adding material to specific areas restores original dimensions and functionality. This capability reduces downtime and extends the service life of components, resulting in cost savings and increased productivity.

Hydraulic Applications

-

Hydraulic Cylinders

Description

DescriptionHigh-pressure hydraulic cylinders need to be resilient and long-lasting to cope with high static and dynamic forces across many industrial purposes such as lifting or jacking, pushing, pulling, or pressing. Due to the vast applications and frequency of use of hydraulic cylinders across industries, reconditioning pistons and parts is a vital part of lifecycle management.

In comparison to traditional hard chrome plating, reconditioning with superior super alloy coating applied with an advanced hard-facing laser cladding process has far greater and longer lasting results increasing the lifecycle. Additionally, laser cladding is a more efficient and safer alternative to traditional hard chrome plating. Known carcinogen hexavalent chromium [Cr(VI)] is a byproduct of hard chromium plating production and should be avoided with safer alternatives.

Hydraulic cylinders come in a range of sizes to suit the requirements of a range of industry applications.

-

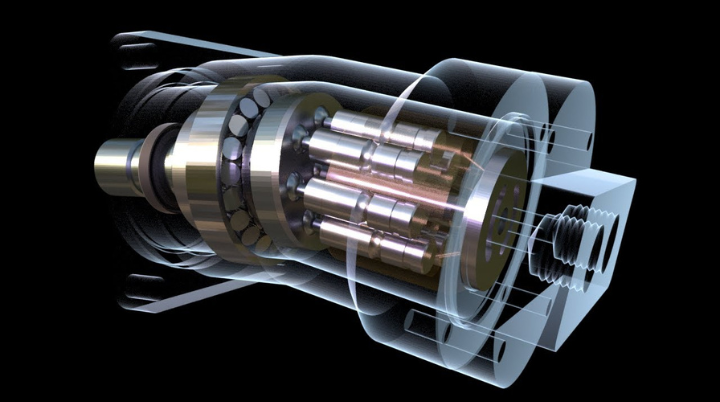

Pump Components

Description

DescriptionVarious types of pumps can be used in hydraulic systems depending on the specific application and requirements. These include gear pumps, vane pumps, piston pumps, screw pumps, bent axis pumps and radial piston pumps.

APEX ETG’s laser cladding can be applied to enhance the performance and longevity of specific hydraulic pump components, such as pump rotors, pump housings, valve plates, shaft journals and bearing surfaces.

-

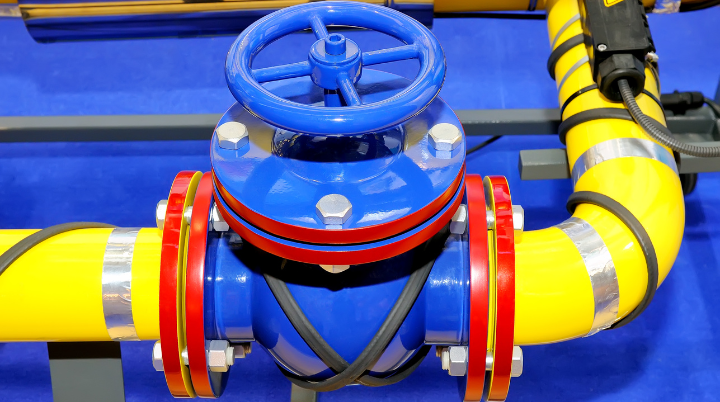

Valve Components

Description

DescriptionAPEX ETG’s laser cladding technology can enhance and repair various components of hydraulic valves. By utilising a laser beam to fuse powdered metal onto valve surfaces, APEX ETG can provide protective coatings, repair damaged components, and improve wear resistance. This process is applicable to valve bodies, spools, seats, and other critical components found in control valves, relief valves, check valves, and proportional valves. The result is increased durability, extended service life, and improved performance for these valve components in hydraulic systems.

-

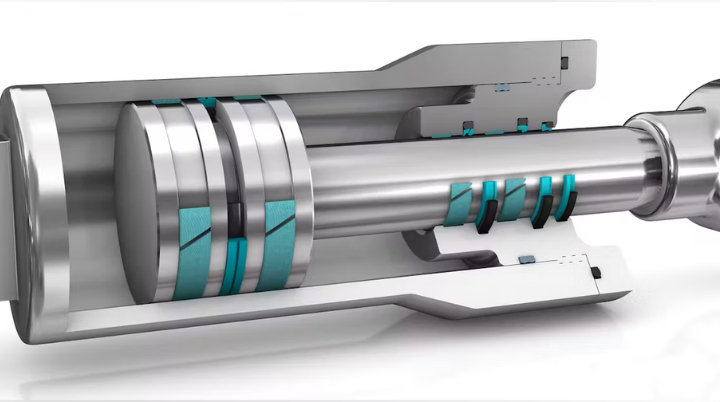

Hydraulic Pistons

Description

DescriptionAPEX ETG’s laser cladding services for hydraulic pistons offer exceptional benefits. Our advanced laser cladding technology enables us to enhance specific parts of hydraulic pistons, including the piston crown, piston skirt, and piston rod. By applying a laser-clad layer, we significantly improve wear resistance, ensuring a longer lifespan for the pistons by protecting them from abrasion and friction. Our laser cladding process also enhances corrosion resistance, safeguarding the pistons against chemical degradation from hydraulic fluids and harsh environments. With precise control over surface properties such as hardness, friction coefficient, and thermal conductivity, we optimize the performance of hydraulic pistons, resulting in increased efficiency and reduced energy losses. By choosing APEX ETG’s laser cladding services, you can count on extended service life, reduced maintenance, and reliable performance for your hydraulic pistons in even the most demanding applications.

-

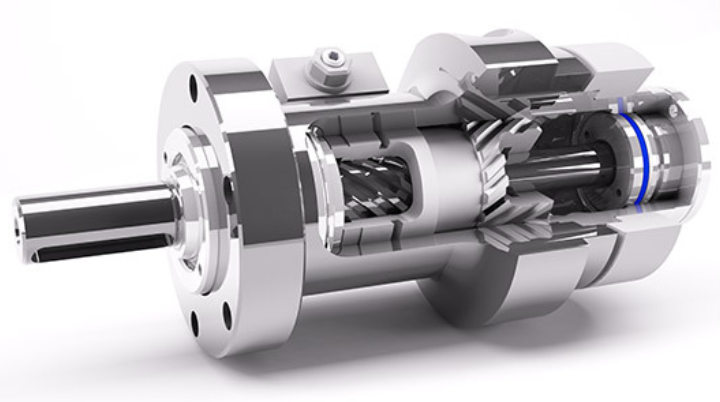

Actuator Components

Description

DescriptionActuators are responsible for initiating and controlling movement, such as opening and closing valves, adjusting positions, driving pumps, or operating mechanical components. APEX ETG’s laser cladding services bring tremendous benefits to actuator components. By laser cladding parts such as actuator pistons, cylinders, valve bodies, and sealing surfaces, we enhance wear resistance, extending their service life. Our process also improves corrosion resistance, safeguarding components from chemical attacks in harsh environments. With tailored surface properties including hardness, friction coefficient, and thermal conductivity, our laser cladding optimises actuator performance, reducing energy losses and ensuring reliability. Choose APEX ETG for enhanced durability, corrosion protection, and custom surface properties in actuator components.

-

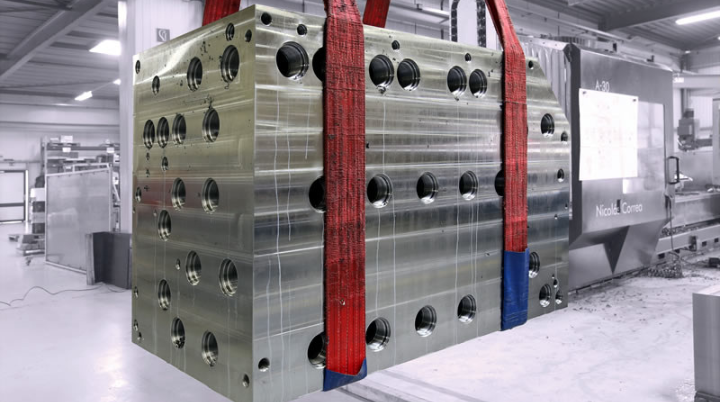

Hydraulic Manifolds

Description

DescriptionAPEX ETG’s laser cladding services provide significant advantages for hydraulic manifolds. Hydraulic manifolds are key components in hydraulic systems responsible for distributing and controlling the flow of hydraulic fluid. By laser cladding hydraulic manifold surfaces, such as channels, ports, and valve seats, we enhance wear resistance, prolonging their lifespan. Additionally, our laser cladding process improves corrosion resistance, protecting the manifold from chemical degradation in demanding environments. With tailored surface properties, including optimised hardness, friction coefficient, and thermal conductivity, our laser cladding enhances the efficiency and reliability of hydraulic manifolds, reducing energy losses and ensuring consistent performance. Choose APEX ETG for extended durability, corrosion protection, and customised surface properties in hydraulic manifolds.

Types of hydraulic cylinders;

Hydraulic cylinders for mobile applications;

- Attachment cylinder

- Boom and luffing cylinder

- Pull cylinder

- Telescopic cylinder

- Ballast cylinder

- Synchronised cylinder

- Plunger cylinder

- Support

Hydraulic cylinders for stationary applications;

- Servo cylinders

- Drive cylinders

- Pitch cylinders

- Luffing cylinders

Applications by Industry

Applications across a range of industries

- Hydraulic jib crane

- Hydraulic Press

- Poly pipe welding machine

- Elevated Work Platform (EWP) machines (scissor lift, boom lifts, cherry pickers, telehandlers)

Civil Engineering

- Hydraulic road sweeper

- Water boring drill rigs

- Tunnel boring machine

- Hydraulic excavator with scrap shear

- Elevated Work Platforms

Construction Machinery

- Mobile cranes

- Carry deck crane

- Crawler cranes

- Telescopic cranes

- Tower cranes

- Road cranes

- Skid machines / bobcats

Marine

- Maritime offshore cranes

- Offshore cable laying

- Pipe tensioning machines

- Underwater drill rigs for underwater pipeline stabilisation

- Marine hydraulic steering systems

- Hydraulic cranes and tender launch systems

- Hydraulic outboard propulsion units

- Hydraulic passenger lifts

- Cargo lifts

Mining

- Exploration drill rigs

- Tough terrain cranes

- Bulk handling cranes

Manufacturing Machines

- Machine tools

- Panel processing machines

- Turning machines

- Die casting machines

- Blow moulding machines

- Plastic injection moulding machines

- Machines for food processing

- Bottle filling machine

- Nibblers

- Polishers

- Presses (e.g. extruders)

- Grinding machines

- Injection moulding machines

- Punch presses

- Stationary scrap presses

- Gear cutting machines

- Goods lift

Manufacturing Plant & Systems

- Motion simulators

- Rides

- Bottle filling plant

- Bottle blowing plant

- Power stations

- Measuring systems

- Test benches

- Satellite dishes

- Sluices

- Cableways

- Ski lifts

- Steelworks

- Continuous caster systems

- Adjustable bridges

Offshore Oil and Gas

- Offshore cranes

- Offshore drill rigs

APEX ETG’s Surface Solutions for Hydraulics

APEX ETG’s laser cladding services effectively address the concerns of hydraulics experts by offering wear and corrosion resistance, precise customisation, material compatibility, cost-effectiveness, and enhanced system reliability. With its remarkable capabilities, laser cladding empowers experts to optimise hydraulic system performance, extend component lifespan, and ensure efficient and reliable operation.