Main Causes Of Wear In The Pump Industry

-

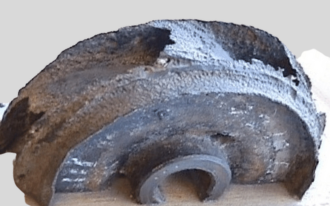

Abrasive wear

Abrasion is the most common cause of wear in pumps. It occurs when the pump is used to handle abrasive materials, such as sand, gravel, or slurries.

APEX ETG’s laser cladding can add a layer of material with superior wear resistance to the surface of the pump components, helping to reduce the effects of abrasion.

-

Erosion

Erosion is caused by the impact of solid particles or high-velocity fluids on the surface of the pump, which can lead to material loss and decreased pump efficiency.

APEX ETG’s laser cladding services add a layer of material that is more resistant to erosion than the original material, helping to protect the pump components from the effects of high-velocity fluids and solid particles.

-

Cavitation

Cavitation occurs when the pressure in the pump drops below the vapor pressure of the liquid being pumped, causing bubbles to form and then collapse, resulting in damage to the pump impeller and other components.

APEX ETG’s laser cladding services can be used to modify the surface properties of the pump components, such as roughness and hardness, to reduce the likelihood of cavitation occurring.

-

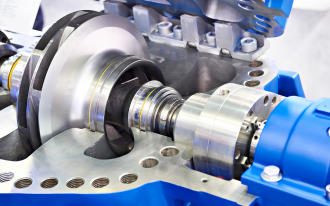

Vibration

Vibration can cause wear in pumps by causing mechanical stress on the components, resulting in cracks or fractures.

APEX ETG’s laser cladding services add material to areas of the pump components that are subject to high levels of vibration, helping to reduce the risk of fatigue failure.

-

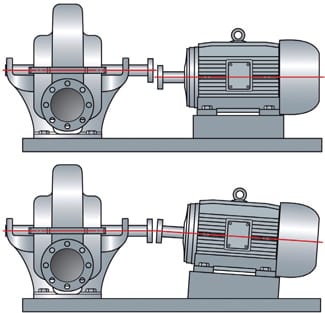

Misalignment

Misalignment of the pump shaft or impeller can cause wear by causing uneven contact and increased friction between the components.

APEX ETG’s laser cladding can add material to the surface of the pump components to compensate for misalignment, helping to reduce the effects of uneven contact and friction.

Applications

- Impellers

- Casings

- Shafts

- Wear Rings

- Seals

- Bearings

APEX ETG’s Surface Solutions for the Australian Pump Industry

APEX ETG’s laser cladding services optimise pump components with benefits like improved wear resistance, precise coating control, enhanced surface properties, reduced downtime, and cost savings. By adding a superior layer of material, the components last longer, require fewer replacements, and enhance performance. APEX ETG restores dimensions for various pump parts, including impellers, shafts, bearing housing, and seals. This efficient process minimises downtime and costs, resulting in improved pump performance, reduced expenses, and increased lifespan.